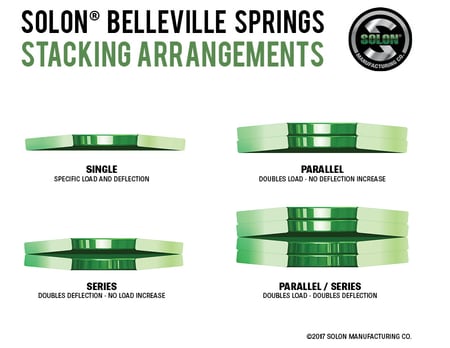

Either a single spring or a stack of springs can be used. Belleville springs can be stacked in a variety of ways.

Series Sp Belleville Spring Index Fan Disc Corporation Fan Disc

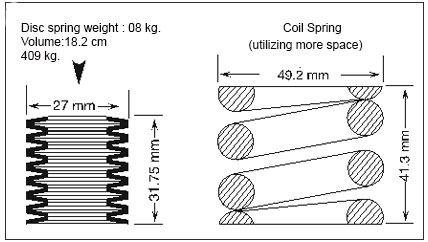

This spring rate is usually very high allowing the spring to produce very large loads in a very small space.

. Disc Springs are conically-shaped washer-type components designed to be axially loaded. Its value should not exceed the value of the tensile strength R m of the material to avoid plastic deformations of the spring ie. Ability to provide stack specific load-deflection diagrams.

What are Disc Springs. The loads are normally applied to the upper inner edge and the lower outer edge. Disc springs can used as single or multiple units.

Disc Springs or Belleville springs. Remove security settings prior to downloading to allow macros to run 2. August 15 2007 33.

Disc springs with a thickness of 05 mm and greater are shot-peened to improve fatigue life Standard corrosion protection is phosphating and oiling. Disc Springs are manufactured to DIN 2093 and designed as per DIN 2092. We Are Committed to Making Your Job Easier - Shop our Endless Aisle.

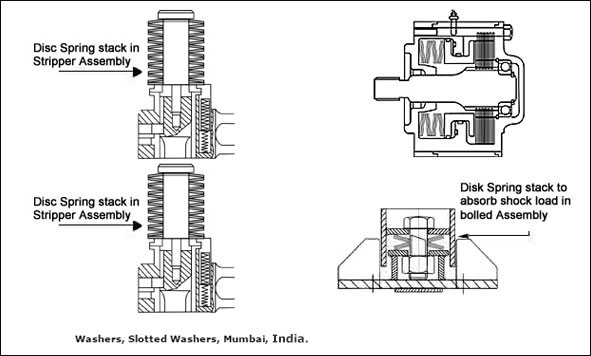

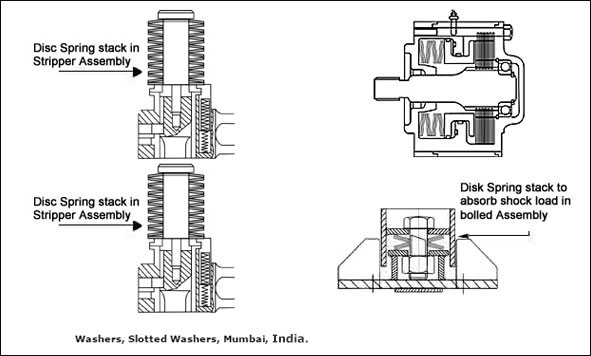

By varying the size and the stacking arrangements an extremely wide variation in operating parameterscan be achieved. Belleville spring disc spring and conical compression washer are all names for the same type of spring. The proper use of disc springs as a modern design element permits substantial economies by size reduction and maximum utilization of energy and space as seen in the examples below.

A Belleville spring is a conical shaped disc that will deflect flatten at a given rate. The standard corrosion protection is zinc phosphating and oiling. A disc spring is a conical shell spring which is loaded along itsaxis.

These washers have also been used in the construction of buildings wherein stacks of disc springs are used under buildings as vibration dampers for earthquakes. The maximum allowable limit is given by the reference stress σ om. Spring Loaded Design The basic spring loaded pressure relief valve has been developed to meet the need for a simple reliable system.

Our group 1 2 Disc Springs are AUSTEMPERED this method of heat treatment is particularly effective for high fatigue Disc Springs. The guide can be on the outside D e or the inside D i of the springs but inside guidance on a bolt or shaft is preferred to the outside guidance in a sleeve because it offers design and economic advantages. Click on the images below to enlarge.

Ad Millions of Items on One Easy-to-Use Site with Outstanding Customer Service. Disc springs are conical shaped washers designed to be loaded in the axial direction F only. These springs are manufactured from Ck 67 and 50 CrV 4 and are typically available from stock.

In the design of a new disc spring a certain stress level should not be surpassed for static loading. Their conical design aids in an easier prediction of their spring characteristics and performance in comparison with traditional compression springs. David Banks-Fear is a Mechanical Design Forum Group member.

A disc spring is a conical shell which can be loaded along its axis either statically or dynamical ly. We have custom design program to assist our customers for their specific applications. A Belleville spring consists of a coned disk as shown in the above figure.

MW Components is committed to providing a quality product and ensuring customer success. DIN 2093 Belleville springs are conical disc springs with elastic properties. TYPICAL disc spring applications.

Spring washers are affected by their slots 8-9. Ad Precision Disc Spring Engineering and Manufacturing. Refer to the PRICE GROUP in the appropriate pricing chart by spring type located in the back of this catalog for pricing up to.

¾-inch maximum outside diameter 2 inches free length 35-pound load at a ½-inch deflection Assume severe service and SG ends made from music wire. With the program open navigate to the second tab located at the bottom of the document named Standard. Disc springs always need a guide element to prevent lateral movement.

Read across to the last column PRICE GROUP to obtain the price code. Ad Easy online search includes pricing and specifications for over 25000 springs. He is a technical author and consultant design engineer with nearly 40 years of experience.

This research is motivated by the current lack of systematic design methods on Belleville spring washers. Disc Springs are available with or without contact flats. Disc springs are washer-like components that are conically shaped.

Disc Springs can be. Select the spring you want by LEE STOCK NUMBER. Automobiles also use this kind of disc spring to reduce vibration and noise.

Guidance of disc spring stacks. Try an outside diameter of 725-inch and solve for D. It is called Belleville spring because it was invented by Julian Belleville who patented its design in France in 1867.

The Standard Product Range of disc springs sizes to DIN 2093 and Factory Standards includes 246 sizes with outside diameters between 8 and 250 mm. Screwed or bolted sections. Belleville spring has a typical load-deflection characteristic as shown in the above figure.

Design a helical compression spring for the following conditions. Download the Excel version of the Disc Spring Calculation Program. You can also navigate to the Extras tab to find additional products from Mubea.

Those who use the information are reminded of. When stacked in multiple unitsthey can be stacked in series to give a low stiffness value or in parallel to give a higher stiffness value. Proper guidance and location of disc springs is essential to their performance and will ensure that the desired characteristics and repeatability is achievedRecommended guide clearances are shown in the tolerance tables and it is also necessary to pay some attention to the nature of the guidance and seating surfacesMuch depends upon the severity of duty in the application eg.

Spring and the disc will lift and allow fluid to flow out through the valve. When applicable select the price code that corresponds to the material type required. Valves piping and drilling tools.

The Story of the Disc Spring Although the disc spring has found a wider. They can be statically loaded either continuously or intermittently or cyclically deflected ie. What makes Disc Springs unique is that based on the standardized calculations of DIN EN 16984 formerly DIN 2092 the deflection for a given load is predictable and the minimum life cycle can be determined.

Other coatings are available Disc spring sTacks On request Daemar can deliver disc springs pre-assembled in stacks or on a guiding device. Unlike conventional coil springs that have many books and publications on their designs Belleville spring washers do not have many publications on their designs. He and his design team are available to assist with any technical design issues with springs pressings and precision engineered parts.

Disc Springs Calculation Formulas Tokai Spring Industries Inc

Belleville Spring An Overview Sciencedirect Topics

Belleville Disc Spring Stack Design Calculator

Belleville Spring Technical Notes Disc Spring Tech Notes

Disc Spring Din 2093 Disc Springs Manufacturers Suppliers Mumbai

Belleville Disc Washer Description Design Considerations Load Deflection Data Wcl Company

Stacking Disc Springs Belleville Springs

Disc Spring Din 2093 Disc Springs Manufacturers Suppliers Mumbai

0 comments

Post a Comment